Custom Solutions

Custom designed HVAC Solutions For Mobile Applications

MORE ON

Booyco’s Custom Systems

Booyco Engineering has been building customised HVAC systems for almost four decades.

To serve our chosen market niche, we are staffed with a large proportion of qualified technical personnel. We have a highly qualified and experienced team of engineers, each of whom have worked on a range of mobile HVAC systems, as well as locomotive Cooling Towers, with varying technical requirements.

Our development projects are managed by using a specification Verification Cross Reference Index (VCRI) to ensure all of our customer requirements are met and properly validated, while our design risks are minimised by using the Design Failure Mode Effect Analysis (D-FMEA) methodology, as well as a Return of Experience (REX) review, throughout the design process.

OUR PROCESS

When we design our custom systems we take into account all external factors, carefully considering and resolving the given challenges to produce a comprehensive solution.

The design then moves onto the Prototyping phase where vigorous testing is done on all products both internally and externally to ensure all compliance measures are met.

The result is a reliable custom system that, coupled with regular maintenance, can serve your operation for decades to come.

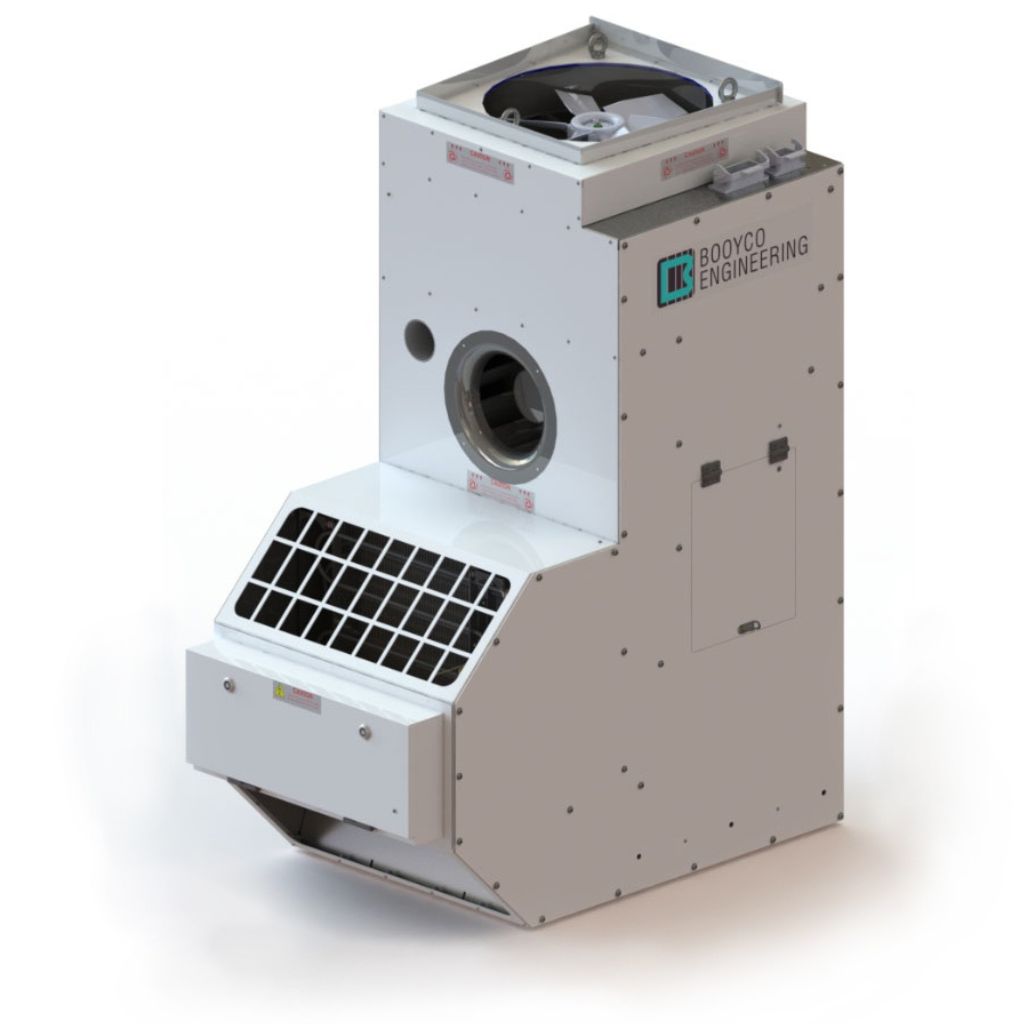

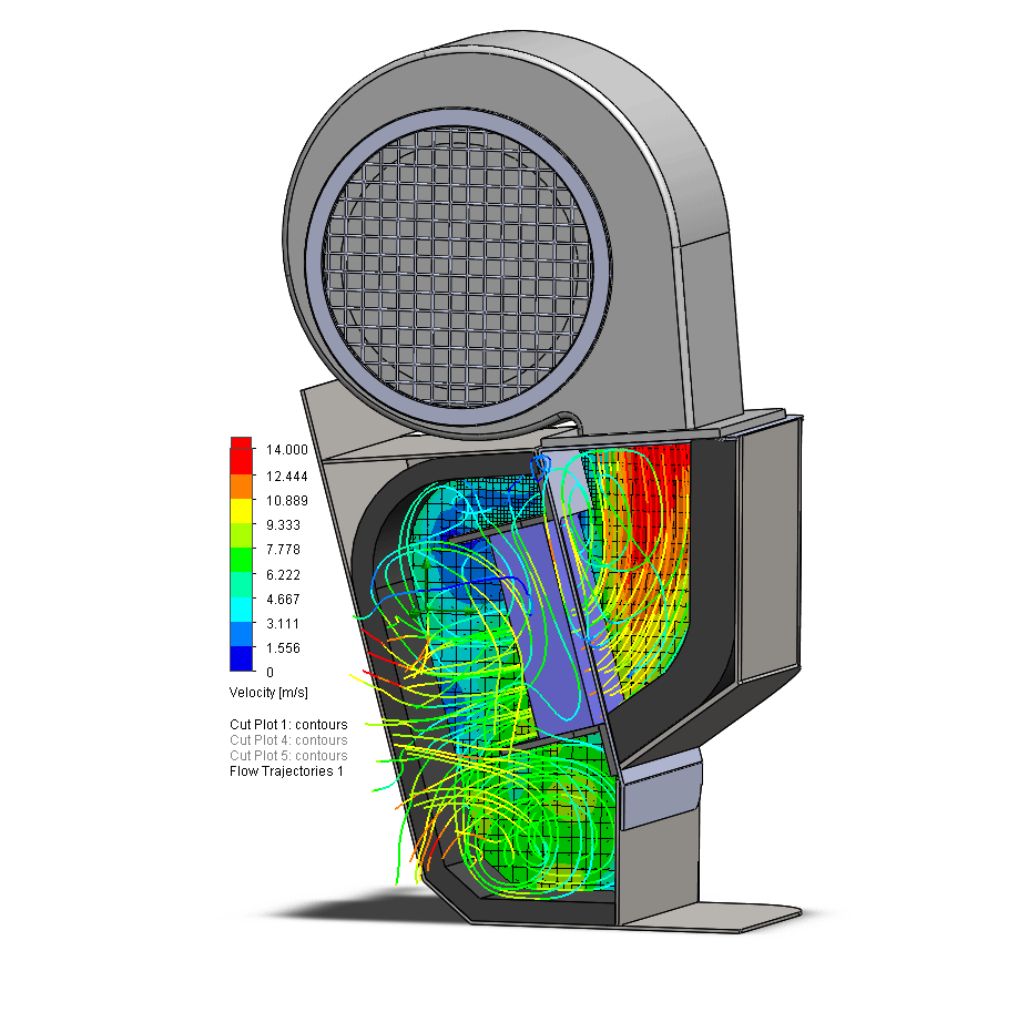

HVAC DESIGN WITH INNOVATIVE SOFTWARE

To optimise our design and design timelines, as well as reduce risk, we utilise many top end engineering design software packages.

Computer Aided Design (CAD) software

- Mechanical and electrical detailing

- Accurate dimensional drawing

- Graphic rendering

- Precise documentation

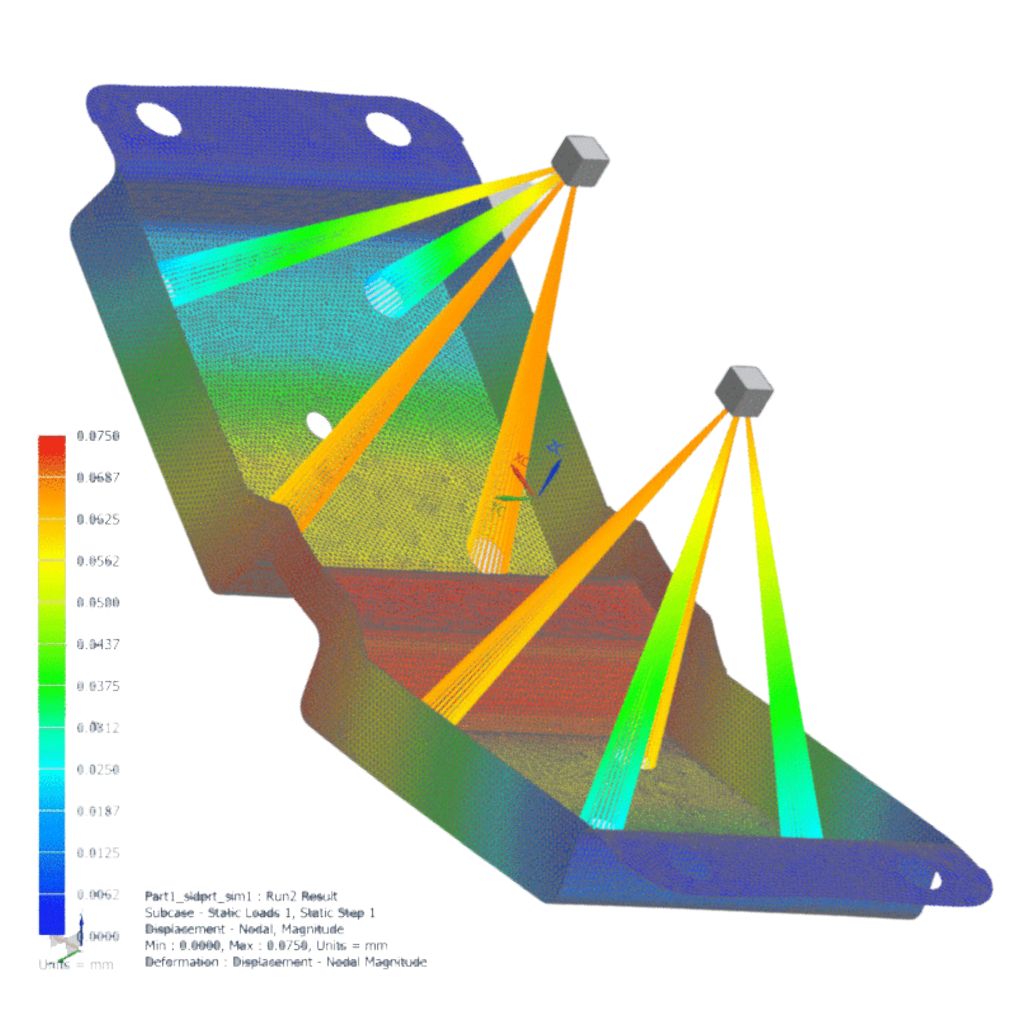

Finite Element Analysis (FEA) using Siemens SimCenter

- Structural and vibration analysis

- Fatigue analysis

- Weld analysis

- Structure borne vibration analysis

Computational Flow Dynamics (CFD)

- Flow distributions and pressure drops

- Room/cabin thermal gradients

- Graphic rendering

- Pull-down/ pull-up simulations

Design data packs are produced using 3-D, parametric modelling, colour, CAD systems in sufficient detail for manufacture to take place. Manufacturing is contracted out to companies who are selected based on the criteria of price, delivery and compliance with our specifications and military requirements. Prototype assembly and type testing is carried out in house.

VIGOROUS TESTING

We have the capability to validate each HVAC design to specific client requirements through various forms of system tests.

Cooling capacity at various ambient and internal conditions

Heating capacity verification

Airflow and airflow distribution

Shock and vibration endurance testing

Acoustic and vibro-acoustic measurements

Electromagnetic compatibility (EMC) compliance testing

Electromagnetic interference (EMI) compliance testing

Functional and control logic verification

Electrical safety – ground bond, insulation resistance, voltage withstand

Power draw, including power factor and start-up current measurement

Temperature and humidity cycling

Solar radiation testing

High/low temperature storage

Ingress protection (IP) verification

Mass verification

Salt spray and salt fog testing

Looking for a custom HVAC SOLUTION?

Get in touch with us, and our experienced team can begin designing your custom solution.